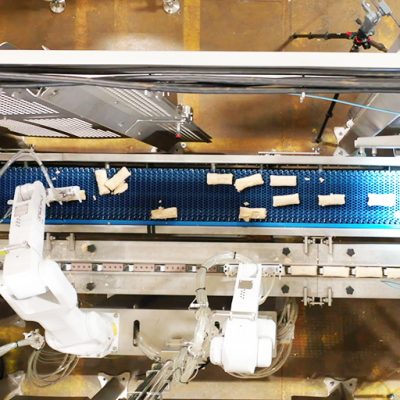

Primary Food Handling

Automation in food manufacturing processes require a number of unique considerations that are not found in other manufacturing or production environments. This is particularly relevant in the handling of primary food items where the tooling and automation infrastructure is in direct contact with raw, prepared and frozen food items. Hygienic materials, tooling, surface and component geometry considerations are all required in order to safely handle these items while preventing product cross contamination, or risk of exposure to bacterial infection such as E-coli or listeria. CIP resistant and capable systems with the ability to handle and / or automatically apply caustic wash-down chemicals and high temperatures are considerations that need to be included into the sanitary design and build process. Articulate end-of-arm tools combined with accurate vision sensors ensure precise handling of variable and delicate product often associated with protein and primary food applications.

Want to know more about what we do?

View BrochureLiterature and Media

What we say, we do. Everytime. All the time.

Our standardized solutions are anything but off the shelf or generic. Instead, they are repeatable, core competence-based systems that we have a reputation of service and quality for across verticals and throughout North America. These solutions are all uniquely JMP, which means that they are uniquely you; collaboratively developed with you, our customer. Standardization simply allows us to provide you with a proven and reliable core system; on time and on budget while providing enough customization to meet your exact specifications.